The automatic gravity filter automatically treats drinking, process and cooling water. Flow rates of 6 to more than 1100 m³/h can be achieved with a single apparatus.

The automatic gravity filter is used, for example, for the filtration of drinking and process water. The filter allows a separation of very fine particles. Additionally, chemicals (e.g. precipitation, flocculation, or sanitisation agents) can be dosed prior to the filtration process. Clear water values of 0-5 mg/l of filterable substances are possible.

In situations with very high soiling of the water to be treated (e.g. river water), a combination with a lamella separator is recommended. The majority of the particles is thereby separated by the lamella separator. Residual particles are then filtered out by the sand filter. The advantages of this combination are the very high operational reliability and an outstanding water quality.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

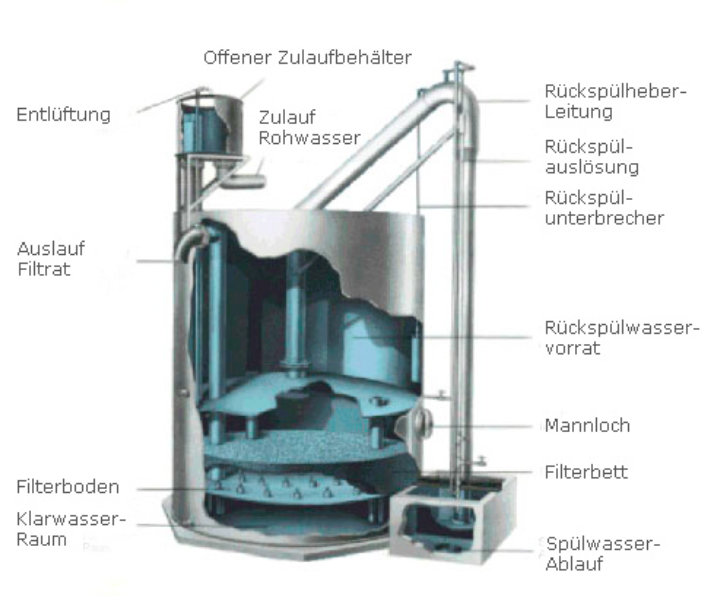

The effluent is pumped into the feed-tank. The water then flows, solely by gravity, through the filter bed into the clear-water-chamber, and eventually up a riser pipe to the outlet.

Dirt particles are held back in the filter bed. The more dirt is held back in the filter bed, the higher the flow resistance, and therefore, the counter pressure rises. This causes the water level in the discharge pipe to rise. The water starts to flow as soon as the highest point of the pipe is reached. The whole backflow-water-chamber is sucked empty due to the siphon effect. The turbulence in the sand bed, needed to wash out the dirt particles, is created by the high backwash velocity. At the end of the backwash process, the flow rate slows down and the sand settles back to a smooth bed.

The feeding of the gravity filter is not interrupted during the backwash process. After the flushing, the backwash chamber gets refilled with filtrate. This process has to be completed before the next filtration can start. The operator should notice that no filtrate is available for about 10 minutes after the backwash process.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the automatic gravity filter.