The vacuum belt filter is used for the filtration of liquids and dewatering of sludges.

Unlike hydrostatically working filters, the filtration is made by gravity with additional vacuum support. As a result, higher throughputs and better dewatering of the filter cake can be achieved. Depending on the application, filter fleeces or

endless filter belts are used.

In many applications, the vacuum belt filter provides an effective alternative to belt filter presses or chamber filter presses as well as centrifuges.

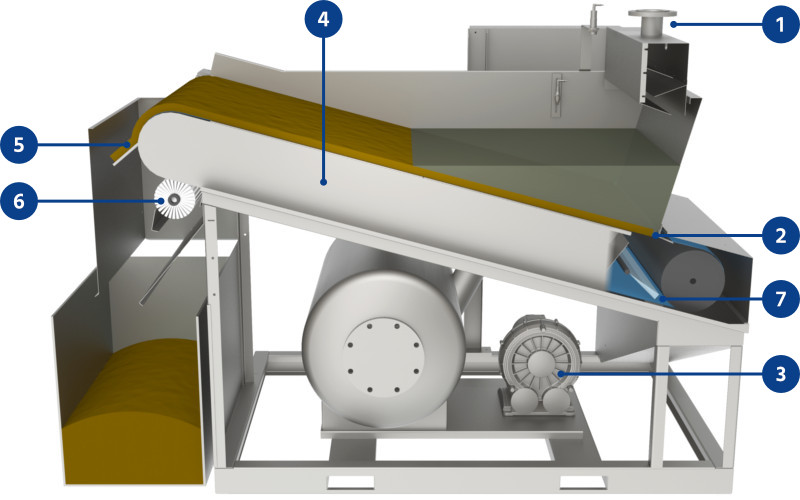

The untreated water is fed into the filter from the top and is spread evenly over the entire filter belt width via the inlet box (❶). The filter belt is fed below the water level (❷). Here, in the lower parts, the filtration process takes place while further up there is the dewatering of the filter cake. Via a side channel compressor (❸) air is sucked off continuously from the filter chamber (❹), whereby a slight vacuum is created on the side of the filtrate.

As soon as the liquid level exceeds a certain level, the vacuum is broken and the filter belt clocks on. The resulting filter cake is separated from the tape by a scraper (❺). The belt is then cleaned with a brush roller (❻) and rinsed with additional high-pressure flushing nozzles (❼).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

The vacuum belt filter is equipped as standard with an endless belt. Alternatively, it is also possible to have a filter fleece instead.

Material | stainless steel |

|---|---|

Filter belt | stainless steel, plastic |

Filter fleece | polyester, viscose, polypropylene |

Alternative materials on request.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the vacuum belt filter.