In addition to non-sedimentable solids and floating materials such as oils and fats, the flotation clarifier also efficiently separates precipitated materials such as suspended solids from liquids. This makes this flotation system particularly suitable for the treatment of process or waste water, which has very high purity requirements.

The flotation clarifier is based on the flotation separation method. By using micro-bubbles, the contaminants float up in the flotation system and are removed at the surface. The microbubbles in the flotation clarifier are generated by the MicroGas™ microbubble generator. In contrast to conventional technologies, such as dissolved air flotation (DAF), this is not based on the principle of gas dissolution, but on the direct induction of microbubbles. Additional lamella packages provide a significantly larger clarification area, allowing even heavier suspended solids to float efficiently.

The combination of the innovative MicroGas™ technology with effective lamella packages provides an excellent flotation result.

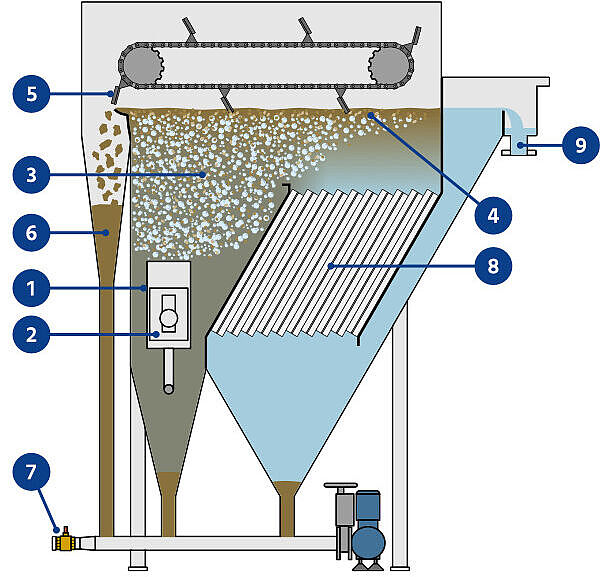

The dirty water enters the clarifier via the inlet (❶) directly to the micro bubble generator (❷). There the contaminants are transported fast upwards with the micro bubbles (❸) and form a sludge carpet at the water surface (❹). This is removed by a surface scraper (❺) and gets over a sludge funnel (❻) to the sludge discharge (❼).

The water flows into the second chamber through the lamella (❽) downwards and from there again upwards to the clear water outlet (❾). In the lamella packag remaining suspended solids - if existing - float upwards and move along the upper side of the lamellas upwards to the sludge carpet.

If the dirty water contains sedimenting particles, they concentrate in the sludge funnels (❿) and are discharged via the sludge outlet.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the rotary screen.

The flotation clarifier is particularly suitable for applications that require a high level of purity. It is mainly used for process and wastewater treatment in the food and petrochemical industries.