The magnetic separator segregates the ferromagnetic particles from liquids e.g. cooling lubricants. It is intensified with emulsions from grinding processes, which are contaminated with fine particles, and are used to prevent blocking of subsequent filters.

The permanent magnet used ensures a higher degree of separation in connection to the robust stainless-steel design and also a long service life. For each magnetic separator up to 900 l/min throughputs with different contaminations are possible.

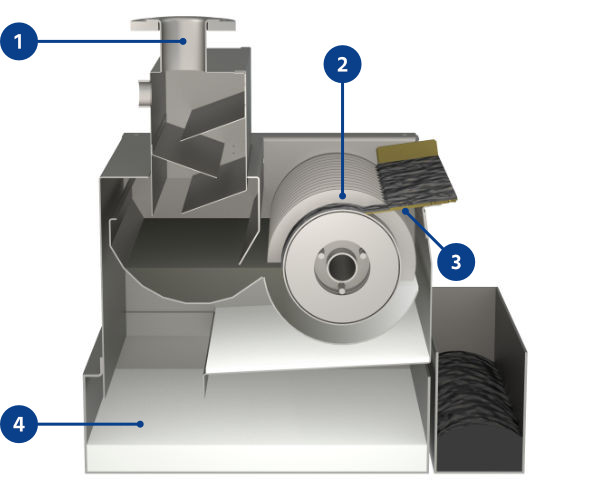

The contaminated liquid is fed into the magnetic separator from above (❶). The ferromagnetic particles are retracted by the extremely strong permanent magnets of a magnetic cylinder (❷) and remain adhered here. By turning the roll, they are transported out of the liquid and separated on a deflector plate (❸). The cleaned liquid flows to the outlet (❹).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

Magnetic separators can be used as an independent compact device or as component in the central filter system.

The chain magnetic separator is a version of the magnet separator, which is especially suitable for large throughputs.

| Material | stainless steel 1.4301 / 1.4404 |

|---|---|

| Magnets | ferrite magnets |

Alternative materials upon request.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the magnetic separator.