The solids separator is used for the separation and dewatering of quickly sedimenting solids (e.g. sand, scale, slag) from waste water or process water.

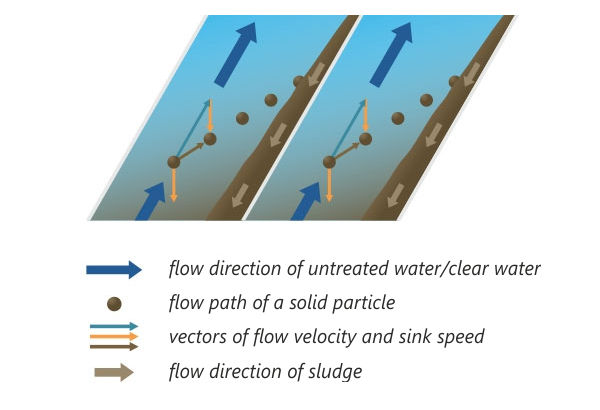

With the help of an integrated lamella pack and the resulting larger settling surface, finer particles can be separated and discharged by a screw conveyer.

The solids separator is used at high volume flows with relatively low solids loading. This distinguishes it from classical separation aggregates of the treatment technology such as bucket wheels, classifying screens or hydrocyclones.

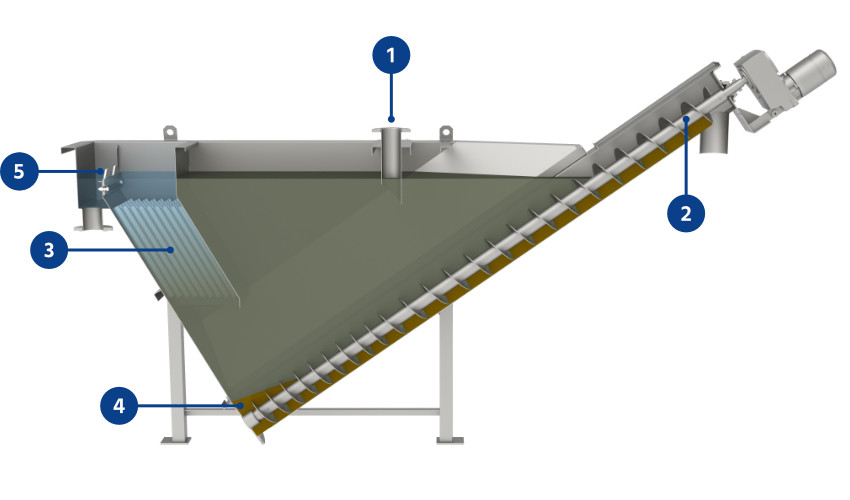

The untreatet water is filled in the container from above (❶). The coarser solids sediment downwards to the screw conveyer and are discharged by it (❷). A subsequent dewatering takes place in the upper part of the screw conveyer above the water level.

The untreated water streams through the lamellae from bottom to top (❸). The solids settle down countercurrently on the lamellae and slide downwards along the lamellae to the screw conveyer (❹).

The treated water flows further upwards and via a special overflow weir to the outlet (❺).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

The solids separator is obtainable with or without lamella packs.

In addition there is the possibility to integrate a surface scraper in order to remove floating sludge.

Materials | coated steel |

|---|---|

Lamellae | polypropylene, stainless steel |

Alternative materials on request

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the solids separator.