The FlowSand-Filter is an upwards flowing spatial filter with continuous filter bed cleaning. In contrast to other filter systems the filtration process is not interrupted for backwashing. Therefore, there is no need for rinsing water tanks, rinsing pumps, buffer tanks for intermittently accruing sludge water as well as complicated

backwashing techniques.

By the principle of volume filtration and the continuous filter bed cleaning the FlowSand-Filter can also be used at high solids loads.

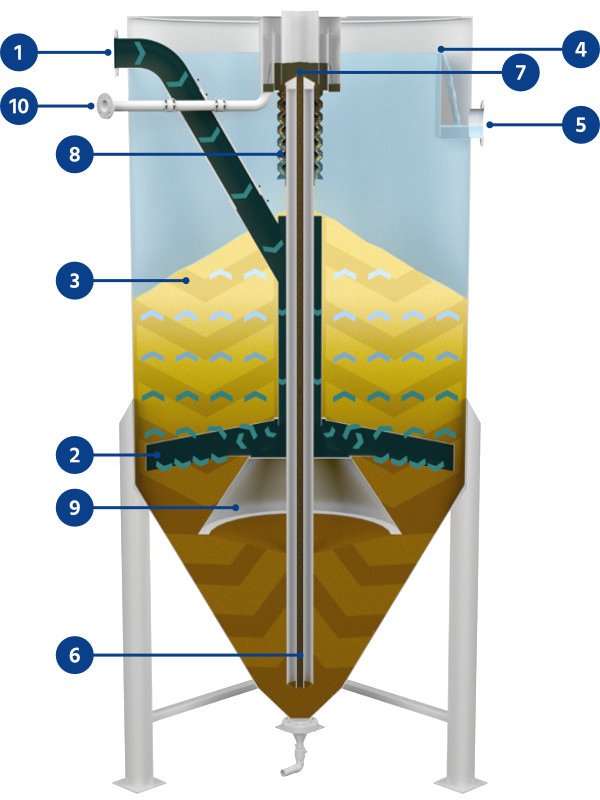

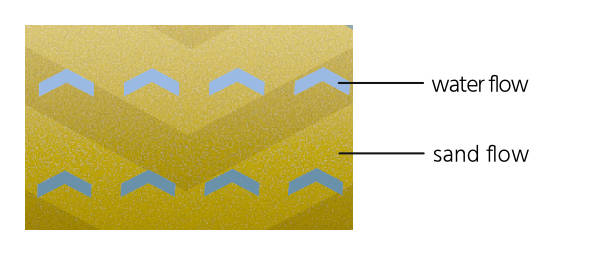

The untreated water flows through the inlet pipe (❶) and the star-shaped inlet distributor (❷) in the sand filter bed (❸). From there it flows through the filter bed from bottom to top being filtrated by the countercurrently downwards moving filter bed.

The filtered water exits the filter by the overflow edge (❹) through the filtrate outlet (❺). The contaminated sand is moved to the calming unit (❼) at the top by using an air lift pump (❻). From there the sand falls into the sand washer (❽), where it is cleaned in countercurrent flow by a partial flow of the filtrate. The cleaned sand falls back onto the surface of the filter bed and serves as a filter medium again. The sand distributor conus (❾) ensures an even distribution of the sand over the whole filter area. The contaminated washing water exits the filter via the washing water outlet (❿).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

The FlowSand-Filter is available in a container or concrete design.

The containers, usually made of steel, are available as single filter or as multiple version, where the latter are consisting of several modularly structured single filters.

The concrete design is mainly used with higher throughput rates. A filter plant in concrete design consists of one or several filter lines, each one consisting of several filter cells. The number of filter lines depends on the throughput rate and on the process conditions. The filter cells of a filter line are open among each other and can be isolated linewise. The untreated water inlet and filtrate outlet are made via an inlet and an outlet channel, the rinsing water outlet via a pipeline.

Materials | stainless steel AISI 304 / AISI 316L; |

|---|

Alternative materials on request.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the FlowSand-Filter.