The depression filter uses a filter fleece medium to filter process fluids. In case of the depression filter, the liquid to be filtered is sucked vertically downwards out of the dirt tank, and through the filter medium. The solid processing residues are thus deposited onto the filter fleece. As time passes, even finer particles are held back,

thanks to the filter cake that is formed. The pumps convey the filtrate directly to the consumers; an intermediate storage tank and additional pumps are not required.

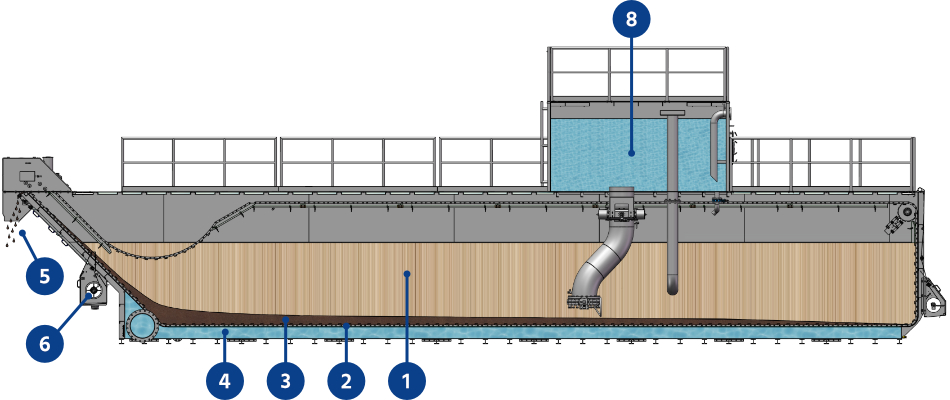

The contaminated cooling lubricant is sucked out of the upper dirt tank (❶), such that it passes through the horizontal filter fleece (❷). The processing residues that are retained on the filter fleece form the filter cake (❸). The suction power of the pumps sucks the filtrate downwards into the clean chamber (❹).

As the filter cake becomes denser, the flow resistance increases, and the vacuum in the clean chamber increases as well. When a vacuum limit value is reached or a predefined period of time has elapsed, the regeneration process is initiated: The vacuum is broken.

The filter then undergoes a clocking procedure, whereby the drag chain transports the processing residues forward to the drop ramp (❺). The contaminated filter fleece is cleaned, and a defined length is rolled up (❻). At the rear side of the depression filter, the same length of new filter fleece is fed in by a roller (❼). The filtration cycle begins anew after the regeneration process has been completed. During the regeneration process, the recipients are fed from a clean tank in an uninterrupted manner; this clean tank is positioned on the dirt tank, and it is filled continuously (❽).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

The depression filter is a rectangular container featuring an integrated chipping discharge facility and a superimposed clean tank. It is therefore particularly compact and spacesaving. The depression filter uses a filter fleece that is selected for the specific filtration task. Thanks to the twin filter design, the required filtrate quantity can quickly be doubled.

Material | coated steel | |

|---|---|---|

Filter fleece | polyester, viscose, polypropylene |

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the depression filter.