The cooling lubricants used during the metal-processing, are contaminated over time by tramp oil, metal chips and grinding disc wear. However, in order to ensure a consistent high quality of the products, a clean cooling lubricant is essential.

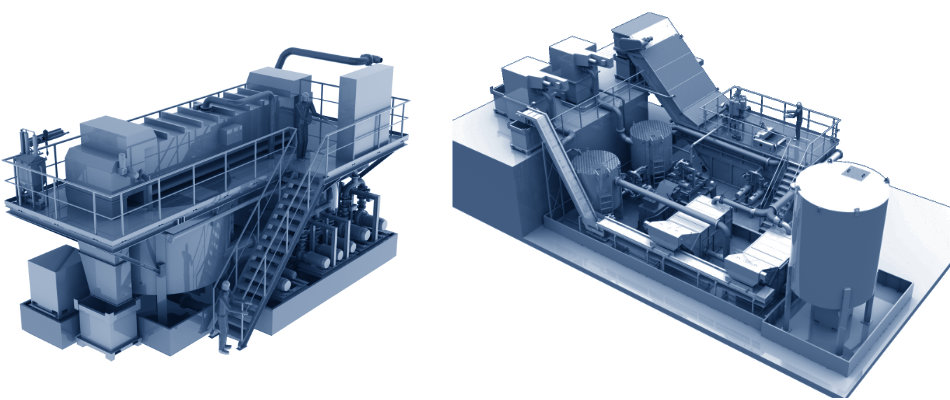

A long-term costefficient alternative for the continuous change of the cooling lubricant is a system for the cleaning of the coolant. In the cooling lubricant central plant, individual filters and separation components are combined by Leiblein in a central system. The solids (material abrasion) and free oils from cooling lubricants are separated in the circulation system.

Cooling lubricant central plants are suitable for the cleaning of larger cooling lubricant quantities, which arise during different processing procedures (Rotating, milling, grinding, honing), are centrally merged and prepared

Depending on the application, a cooling lubricant central plant incorporates both the following cleaning levels:

This is ensured using different procedures like filtration, sedimentation and coalescence. Leiblein's filter and separator offer a large combination variety for the optimal solution of each specific requirement.

If required, other components such as cooling systems and chipping disposal are integrated in the cooling lubricant central plant. In addition, each cooling lubricant central plant is adjusted individually to the spacial requirement, throughput and contamination degree.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the cooling lubricant central plant.