The inclined filter is a hydrostatic working fleece belt filter which is used for filtering industrial liquids. With the inclined filter, both, filterable and floating solids can be separated. The filter fleece is selected according to the application.

There are different materials and fineness of about 5-100 μm available. Depending on the solids concentration and viscosity of the fluid, throughput rates in excess of 50 m³/h per filter can be achieved.

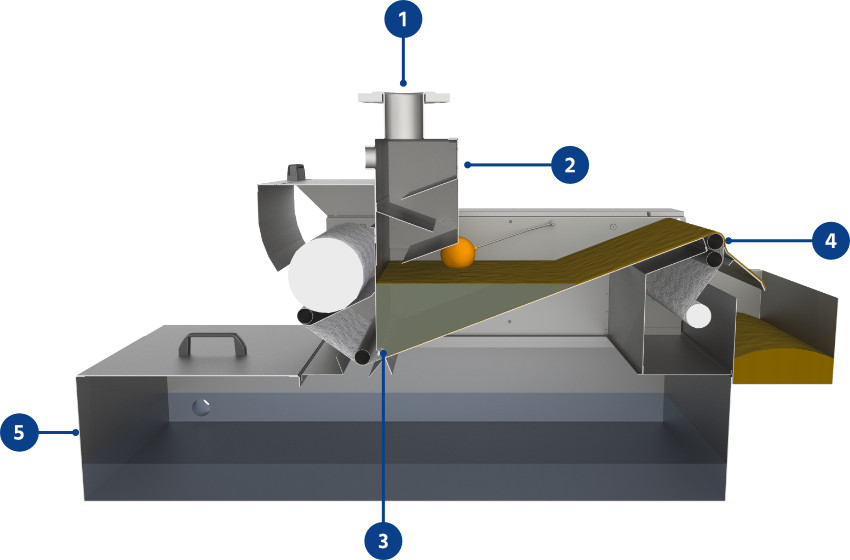

The contaminated liquid is fed into the filter from the top (❶) and is spread evenly over the entire fleece width via a cascade box (❷). The filter fleece is fed into the water chamber from the bottom (❸). The filtration process takes place in the lower part of the inclined plane. Further up there is the subsequent dewatering of the resulting filter cake. Once a certain liquid level above the filter cake is reached, the fleece is pulled upwards with a gear motor.

The filter cake is stripped off via a scraper (❹) and the fleece is rolled up by a roll up pulley. The simultaneously redrawn fleece at the lower end of the inclined plane has a lower flow resistance, so the liquid level decreases and the gear motor stops. The filtrate that passed the fleece, flows into the filtrate tank (❺) and is available for further use.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

Economical and efficient

Quality and Environment

Inclined filters can be used as a standalone compact unit and in combination as a central filter plant by coupling several filters.

In addition to the standard version including a filter fleece, it is possible to equip the inclined filter with an endless belt. Another alternative is the version with vacuum assistance.

Material | stainless steel AISI 304 | |

|---|---|---|

Filter fleece | polyester, viscose, polypropylene in fineness 5 – 100 μm | |

Filter belt | stainless steel, plastic |

Alternative materials on request.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the inclined filter.