The Leiblein coalescence separators cleans emulsions such as cooling lubricants and frees them of tramp oils. It is suitable mainly for mediums, which are very rarely contaminated with solids. With the help of the large surface, which forms due to the filling material, a high oilseparation can be achieved for the liquid / liquid separation.

The Leiblein coalescence separators are mainly used to separate foreign oils from the cooling lubricant. Other uses are e.g. degreasing baths or glass grinding water used in the hollow glass manufacturing. For this reason they are perfectly suitable for the use in circulation systems. Another field of application is e.g. the pretreatment of oil emulsive waste water and cleaning water. Depending on the solids content in a liquid, the lamella coalescence separator or the filler material coalescence separator is used.

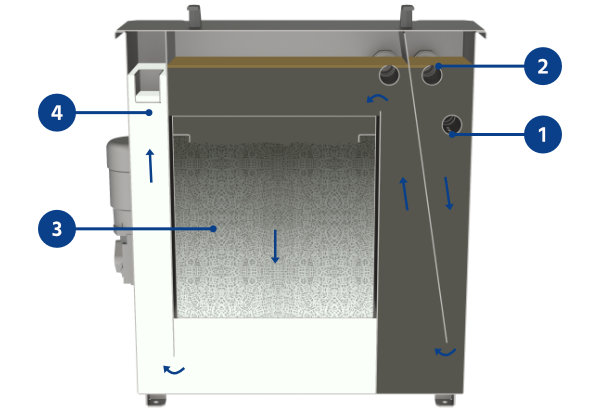

The lamella-coalescence separator cleans liquids such as cooling lubricants and frees them of tramp oils and solids. Thus, the service life of cooling lubricants is increased. The lamella-coalescence separator is designed for the bypass operation and hence mobile application is possible. Due to a very low flow rate a higher degree of separation can be reached. In addition, it is possible to reach each production field through an intelligent design of the lamella-coalescence separator..

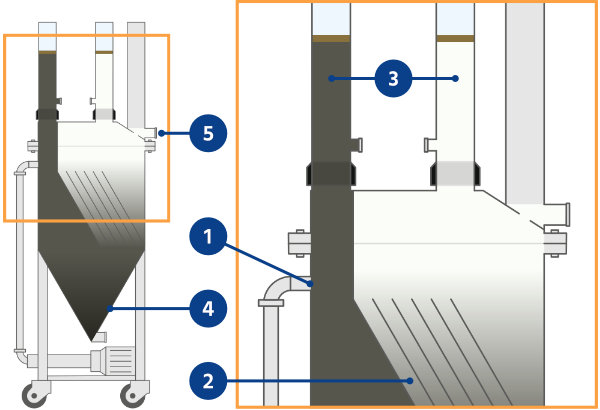

The filler material-coalescence separator cleans emulsions such as cooling lubricants and frees them of tramp oils. It is suitable mainly for mediums, which are very rarely contaminated with solids. With the help of the large surface, which forms due to the filling material, a high oilseparation can be achieved for the liquid/liquid separation.

The contaminated emulsion is pumped in the separator (❶), where it flows through the inclined lamella panel to the top. In the lamella (❷) fine droplets of the tramp oil accumulate on the bottom side of the plate, join to form bigger drops, ascend to the top due to their buoyancy and collect in the separator tubes (❸). The solids sink to the upper side of the lamella panel and slide down into the sludge funnel (❹). The purified emulsion leaves the SPKA through the drain (❺).

Through the inlet chamber (❶) the contaminated emulsion is led downwards. Large tramp oil drops collect on the surface and are removed using the effluent weir (❷). The emulsion flows to the top and from there again downward through the filling material (❸). In doing so, small tramp oil drops do accumulate to the filling material and join to large drops, which now can also rise to the surface, and are separated there. The cleaned emulsion flows to the outlet chamber (❹).

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the coalescence separators.