Precoat filters are used for the fine filtration of cooling lubricants (oil) during finishing and honing as well as for the filtration of other oils and bathswith especially high purity standards. For a consistently high production quality and surface quality of the processed workpieces, the correct filtration of the cooling lubricants, oils and baths is very important.

Precoat filters are frequently used in the metal processing industry e.g. for filtering particles from honing and grinding oils. They can be equipped with different filter cartridges: Slot screen cartridge, Stainless steel-fabric cartridge or plastic-supporting body-cartridge. The filter surface for each dome is between 10 m² and 60 m².

Through parallel coupling of several redundant filter domes, a large central precoat filter system can be built, which raises the production security to a maximum value.

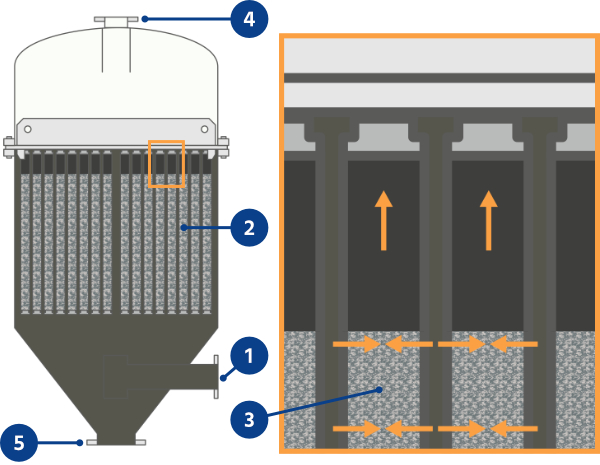

Filter aid (e.g. cellulose) is mixed with cleaned oil for the aggradation and pumped to the filter dome (❶). There the suspension is on the filter cartridges and forms a filter layer (❷). When it reaches a certain strength the filtration process starts. The contaminated oil is pumped in the filter dome and filtered by the filter cartridges with the cellulose layer from outside to inside (❸). When a pressure limit value is reached, the filtration is stopped, the cleaned oil is pumped from the clean tank (❹) and the filter dome is backflushed with the help of pressurized air. The content of the dome is completely emptied in an aggradation tank (❺) and from there rained using a secondary filter. The aggradation process restarts.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the precoat filter.