The lamella separator (also lamella clarifier) separates settleable solids (particles) from liquids and is used for instance in the treatment of process water and waste water.

Basically all solids that sediment in a given time, can be separated easily and economically with the lamella separator. Depending on the density those are usually solids larger than approximately 50 μm in diameter. For separating smaller particles and turbid substances, flocculants are used in order to create settleable flakes.

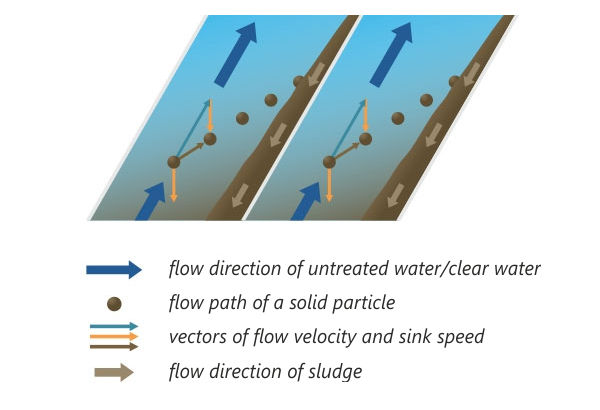

The lamella separator is a pressure-less system. The untreated water is pumped or flows by gravity into the inlet channel of the lamella clarifier where it flows downwards (❶). Below the lamellae the flow is reversed and streams up through the lamellae (❷). The solids settle down countercurrently on the lamellae (❸).

The clarified water flows further upwards and via a special overflow weir to the outlet (❹). The solids slide down along the lamellae and accumulate in the sludge funnel (❺). In order to keep the sludge flowable it is possible to add a scraper in the area of the funnel tip. Depending on the subsequent process steps the sludge is continuously or discontinuously removed (❻).

Cross section lamella packs

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

The lamella clarifier is offered as standard design and as special construction which can be designed, manufactured and delivered from laboratory size to industrial dimensions. Depending on the case of application they can be extended by different add-on parts.

| Materials | coated steel stainless steel AISI 304 / AISI 316L |

|---|---|

| Coatings | special coating to rubber coating |

Lamellae | polypropylene, stainless steel |

Alternative materials on request

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the lamella separator.

Whether treatment of fruit and vegetable washing water, cooling water treatment in chemical or steel plants, cleaning of grinding water in natural stone or glass processing, process water recirculation in gravel plants or wastewater treatment at large construction sites:

Our lamella separators/lamella clarifiers perform effective separation of sedimenting solids in a wide range of industries. They are used successfully and sustainably in numerous applications.