The dewatering container (also drainage container, separation container) is used for sludge dewatering or transportation. Leiblein dewatering containers are low-cost solutions for dewatering of small loads of mineral sludge.

The sludge drains to compact sludge, which can be transported in the container. The sludge can easily be dumped and comes off the geotextile without manual assistance.

The main field of application of the dewatering container is the drainage of mineral sludge, as for example from stone cutting or grinding processes, on constructions sites, from truck wash, as well as diverse wash waters.

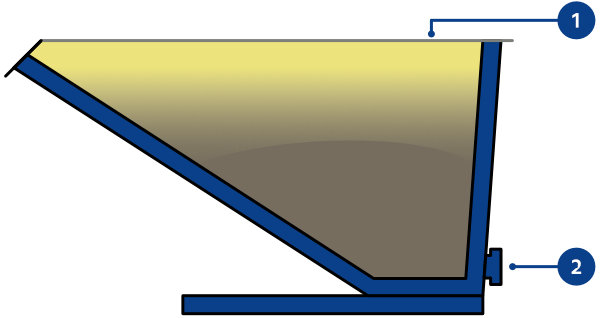

The dewatering container comprises a container and an inserted basket covered with geotextile. The liquid sludge is pumped from the top (❶) into the container. The particles are retained by the geotextile, whereas it lets the water pass and run off through an outlet (❷).

The filling of the container can be done in batches or continuous processes. The filtrate can be disposed or fed back into the cycle.

Our products are available to rent for pilot tests. Due to our extensive rental park, we can put together complete test systems individually for your task.

Advantages of dewatering containers when compared with dumping basins/skip trailers

Advantages when compared with bag systems/big-bags

Advantages when compared with chamber filter press, decanter and belt filter press

Two types of dewatering containers manufactured by Leiblein are available. One type is a tilt-container for use with forklifts and the other a tipping trough for trucks. Both types allow easy filtering, dewatering and transportation of the sludge.

Dewatering container type A

Container volume of 0,5 m³–2 m³, designed as self-tilting-skip for the use with fork lifts

Dewatering container type B

Container volume of 3 m³–12 m³, designed as a tipping trough for the use with trucks

We would be pleased to advice you and will gladly send you more information like type series and measurement sheets of the dewatering container.